Ameracat major repair

2 posters

Ameracat major repair

Ameracat major repair

Hi there,

Appreciate the opportunity to get help/consultation on ordering materials (and any advice on repair).

Ground out a 23" crack where the sponson meet the tunnel on my 31 Ameracat. Found bad news underneath - the crack went all the way through and as I removed material I found acres of empty space that is supposed to be filled completely with foam. The construction top to bottom was deck, a small space supposed to be filled with foam not sure what this space is for, a 3" PVC rigging tubes glassed over and supposed to be surrounded by foam, that PVC rests on another layer of glass which I'd describe as the ceiling of the tunnel, then below that the sponson is supposed to be filled with foam. I have empty space between the deck and glass over the rigging tubes, as well as adjacent to the rigging tubes traveling well down the inside of the tunnel). I believe the manufacturer failed to pour the right amount of foam or poured to slowly so it didn't flow before expanding.

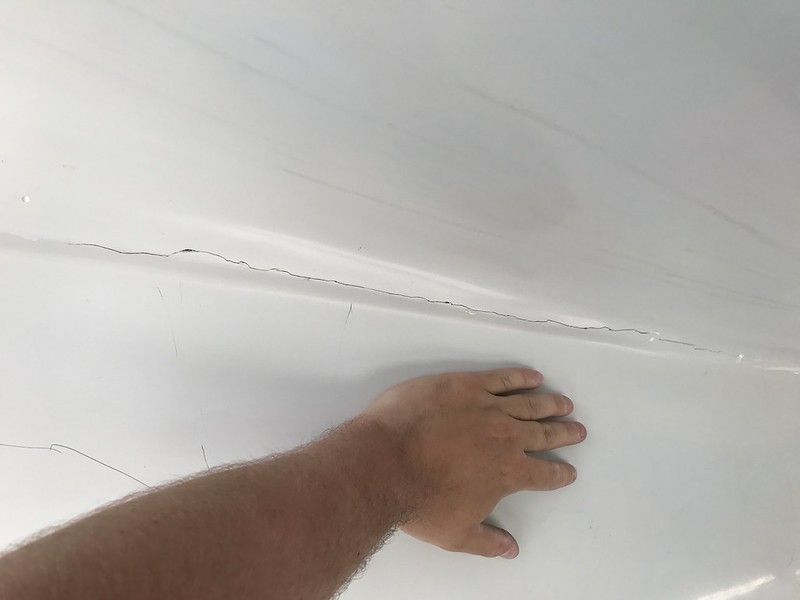

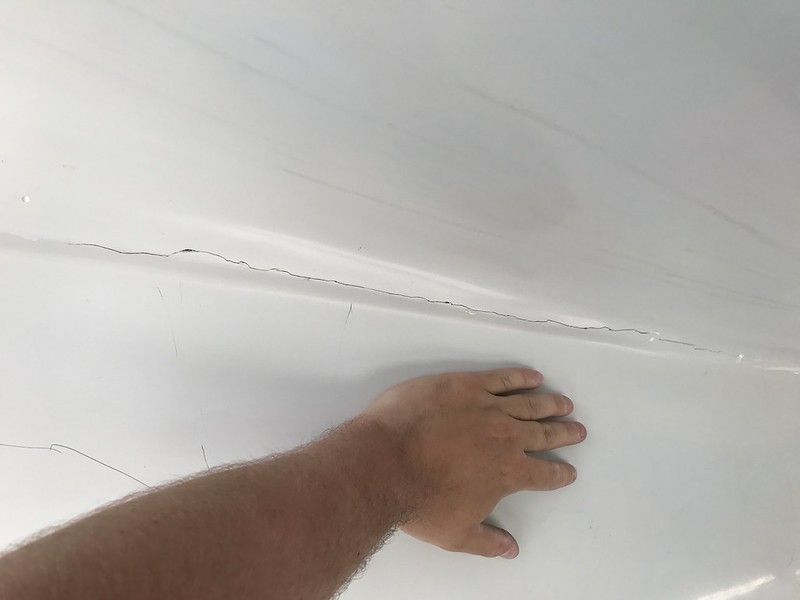

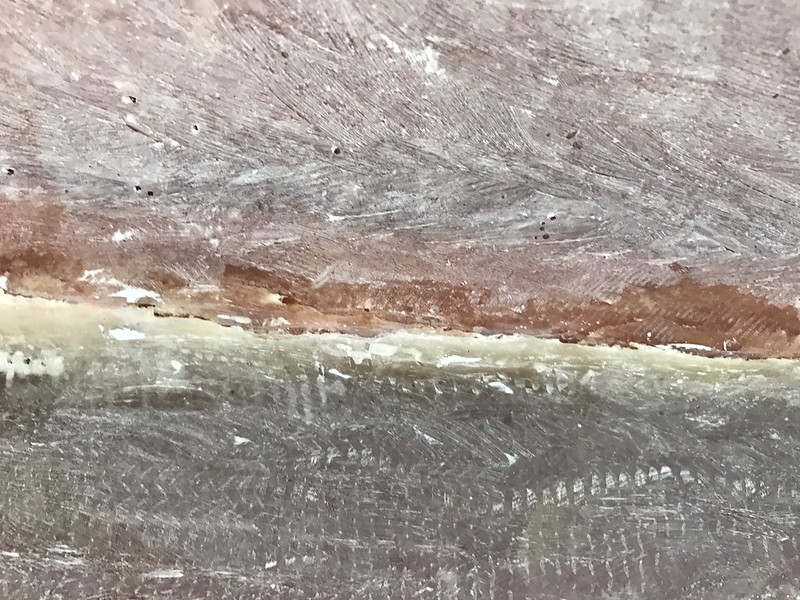

Orignal crack:

Crack kept going:

ameracat resin rich and cracks by Josh Kaptur, on Flickr

ameracat resin rich and cracks by Josh Kaptur, on Flickr

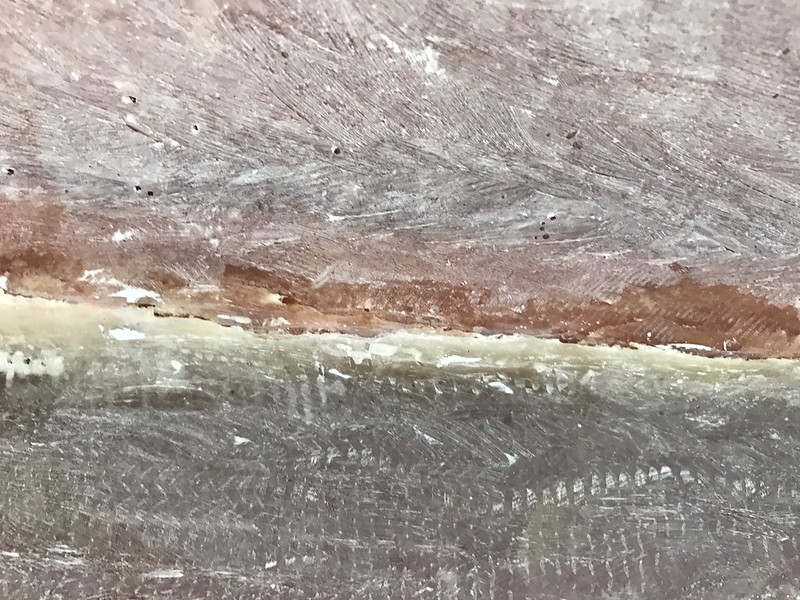

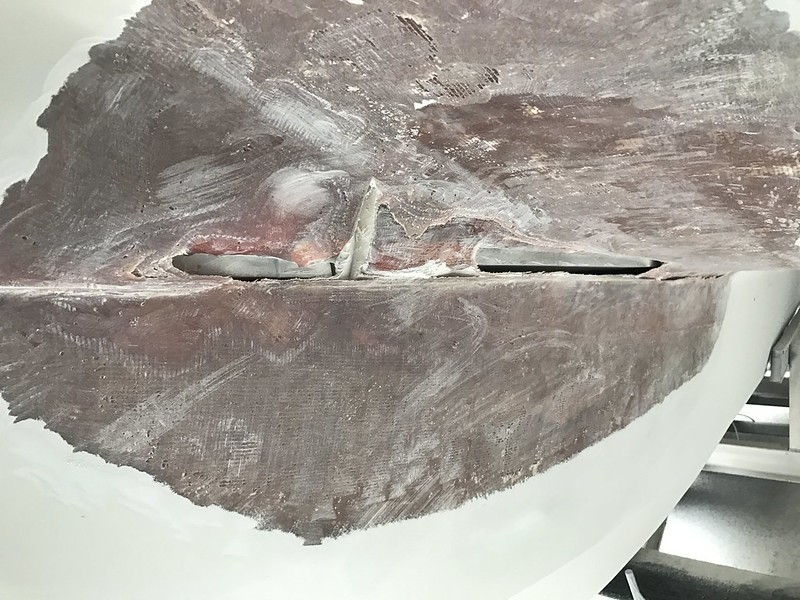

Total grind to get to clean glass (there's a matching one on the other side):

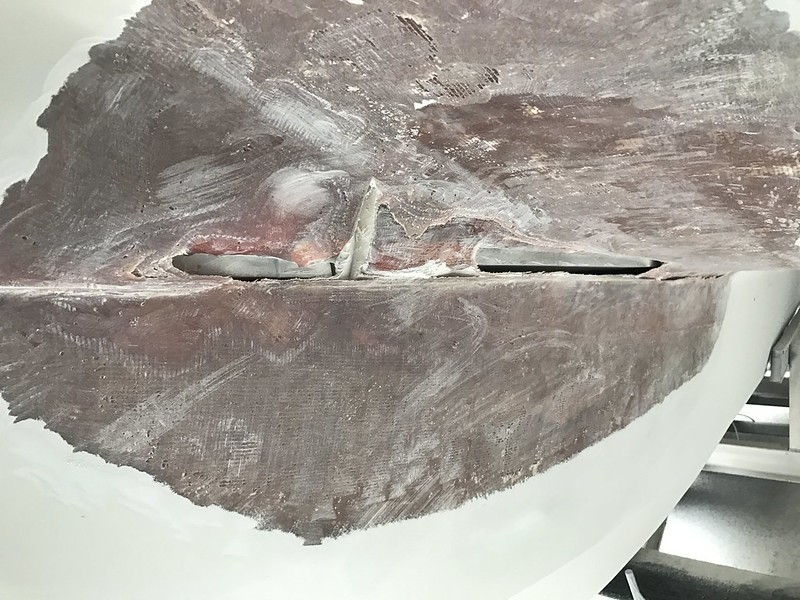

Void under deck:

Void adjacent to rigging tube (that's glass on top, the voids in pic one and this pic are compartmented off from each other through glass that had cracked:

I have decided not to remove the deck and foam and add bulkhead/stringer support (which several people advised) because the boat lasted 2000 hours with these voids. Instead, I have ground out the crack completely, including a huge bevel/scarf. I will glass the tunnel to underside of airex deck and then glass hull side to underside of airex deck (nothing was glassed to the bottom of the airex previously... basically forming a glass T off the floor to the tunnel/hullside), then lay up several layers of glass running the length of the tunnel/hullside radius (repair from exterior). Finally, I plan to pour 6-8 pound foam to fill the voids... I believe 2 # was original... I've cut 2 holes in the deck on each side (accessing the rigging tube area), and 2 holes in the hullside on each side (accessing the inside of the sponson), to accomplish this.

Original laminate was just shy of 1/2" thick. I probably have a 3 foot tall by 5 foot long grind to repair on both sides. I assume those caverns keep going and plan to pour foam on a steep incline. I think my materials list is complete but struggling with how much to order:

Raka epoxy and hardener

1708 and CSM (powder binder)

silica or glass fiber filler (I need to shape the edge of that airex to tunnel shape, and glue/glass the hullside/ceiling joint back)

foam

fairing filler

primer

quantum paint (I'm just covering the repair now... will re-do the rest another time... don't care about blend at all).

Any help is appreciated.

Appreciate the opportunity to get help/consultation on ordering materials (and any advice on repair).

Ground out a 23" crack where the sponson meet the tunnel on my 31 Ameracat. Found bad news underneath - the crack went all the way through and as I removed material I found acres of empty space that is supposed to be filled completely with foam. The construction top to bottom was deck, a small space supposed to be filled with foam not sure what this space is for, a 3" PVC rigging tubes glassed over and supposed to be surrounded by foam, that PVC rests on another layer of glass which I'd describe as the ceiling of the tunnel, then below that the sponson is supposed to be filled with foam. I have empty space between the deck and glass over the rigging tubes, as well as adjacent to the rigging tubes traveling well down the inside of the tunnel). I believe the manufacturer failed to pour the right amount of foam or poured to slowly so it didn't flow before expanding.

Orignal crack:

Crack kept going:

ameracat resin rich and cracks by Josh Kaptur, on Flickr

ameracat resin rich and cracks by Josh Kaptur, on FlickrTotal grind to get to clean glass (there's a matching one on the other side):

Void under deck:

Void adjacent to rigging tube (that's glass on top, the voids in pic one and this pic are compartmented off from each other through glass that had cracked:

I have decided not to remove the deck and foam and add bulkhead/stringer support (which several people advised) because the boat lasted 2000 hours with these voids. Instead, I have ground out the crack completely, including a huge bevel/scarf. I will glass the tunnel to underside of airex deck and then glass hull side to underside of airex deck (nothing was glassed to the bottom of the airex previously... basically forming a glass T off the floor to the tunnel/hullside), then lay up several layers of glass running the length of the tunnel/hullside radius (repair from exterior). Finally, I plan to pour 6-8 pound foam to fill the voids... I believe 2 # was original... I've cut 2 holes in the deck on each side (accessing the rigging tube area), and 2 holes in the hullside on each side (accessing the inside of the sponson), to accomplish this.

Original laminate was just shy of 1/2" thick. I probably have a 3 foot tall by 5 foot long grind to repair on both sides. I assume those caverns keep going and plan to pour foam on a steep incline. I think my materials list is complete but struggling with how much to order:

Raka epoxy and hardener

1708 and CSM (powder binder)

silica or glass fiber filler (I need to shape the edge of that airex to tunnel shape, and glue/glass the hullside/ceiling joint back)

foam

fairing filler

primer

quantum paint (I'm just covering the repair now... will re-do the rest another time... don't care about blend at all).

Any help is appreciated.

JoshKaptur- Posts : 4

Join date : 2017-06-05

Re: Ameracat major repair

Re: Ameracat major repair

Hello,

I think you have a good handle on how to do this, and dont disagree with the any of the approach. The only issue is that the epoxy laminate, while stronger, is more flexible than the poly laminate of the rest of the boat, os your repair will be stronger, but it will flex more. So long as the areas on either side of the crack are well supported (with a frame or something) then should not be a problem. If there is any access to the inside, I would be trying to find a way to put a stiffener on the backside.

6 or 8 lb foam is way overkill

For quantities: Hard to say exactly but a 1/2" of glass ,even beveled back, takes a lot of glass to build up. I would say get 5 yards at least of 1708. 3 gallon kit of epoxy. 1 bag of silica, 1 bag of milled fibers, 1 bag of fairing mix. 2 quarts primer. Paint

let me know if you have more questions, now that Im subscribed I will get immediate notifications on replies to this thread

I think you have a good handle on how to do this, and dont disagree with the any of the approach. The only issue is that the epoxy laminate, while stronger, is more flexible than the poly laminate of the rest of the boat, os your repair will be stronger, but it will flex more. So long as the areas on either side of the crack are well supported (with a frame or something) then should not be a problem. If there is any access to the inside, I would be trying to find a way to put a stiffener on the backside.

6 or 8 lb foam is way overkill

For quantities: Hard to say exactly but a 1/2" of glass ,even beveled back, takes a lot of glass to build up. I would say get 5 yards at least of 1708. 3 gallon kit of epoxy. 1 bag of silica, 1 bag of milled fibers, 1 bag of fairing mix. 2 quarts primer. Paint

let me know if you have more questions, now that Im subscribed I will get immediate notifications on replies to this thread

Re: Ameracat major repair

Re: Ameracat major repair

Thanks, really appreciate your advice.

Reinforcing from the inside (additional glass/bulkheads) is plan B... trying to get this done without taking up the deck (there is zero access and the floor is structural in this boat... no transverse bulkheads across tunnel). If my repair fails then I'll bite the bullet and pull the deck.

6-8 pound foam was an effort to reinforce somewhat from the back without pulling the deck. My thinking was the cavity where the rigging tube is glassed in (last picture) would be filled with "structural foam" -- same thing for the space under the deck which is where the radius of the tunnel is.

I may give you guys a call because I'd like to order in time for the weekend.

Josh

Reinforcing from the inside (additional glass/bulkheads) is plan B... trying to get this done without taking up the deck (there is zero access and the floor is structural in this boat... no transverse bulkheads across tunnel). If my repair fails then I'll bite the bullet and pull the deck.

6-8 pound foam was an effort to reinforce somewhat from the back without pulling the deck. My thinking was the cavity where the rigging tube is glassed in (last picture) would be filled with "structural foam" -- same thing for the space under the deck which is where the radius of the tunnel is.

I may give you guys a call because I'd like to order in time for the weekend.

Josh

JoshKaptur- Posts : 4

Join date : 2017-06-05

Re: Ameracat major repair

Re: Ameracat major repair

Sounds good. The higher density foam will offer some stiffness, but if there is flexing it will pop loose. PU foam has poor peel and sheer strength.

We are pretty fast in shipping, fastest was is through website but you can call it in and I can enter it, whichever works for you 772-633-7923

Joel

We are pretty fast in shipping, fastest was is through website but you can call it in and I can enter it, whichever works for you 772-633-7923

Joel

Re: Ameracat major repair

Re: Ameracat major repair

Just got my order in. Paid $150 for shipping upgrade. Any chance you could have it here by end of day Friday or Saturday morning latest?

JoshKaptur- Posts : 4

Join date : 2017-06-05

Re: Ameracat major repair

Re: Ameracat major repair

JoshKaptur wrote:Just got my order in. Paid $150 for shipping upgrade. Any chance you could have it here by end of day Friday or Saturday morning latest?

Yes, we can send it second day and get it there on Friday.

Re: Ameracat major repair

Re: Ameracat major repair

Sorry for a dumb question... Lots of youtube videos have folks tracing patterns onto clear plastic sheeting to assist with cutting cloth to size. Any advice on where I can get this or the right search term? Preferably amazon.

JoshKaptur- Posts : 4

Join date : 2017-06-05

Re: Ameracat major repair

Re: Ameracat major repair

I have never used clear plastic for patterns. Not entirely sure I would use any patterns for this. You will be layering in a few layers at a time to build up. After the first few layers are up, you will need to let it harden, then come back and clean up the edges with a grinder, then add more. Its really too much to try and do one one shot.

Permissions in this forum:

You cannot reply to topics in this forum